Ultimate Guide to Skim Coating Walls: Detailed Techniques, Costs, and Expert Insights

Mastering Wall Skim Coating: From Selection to Application, Enhance Your Interior with Smooth Finishes

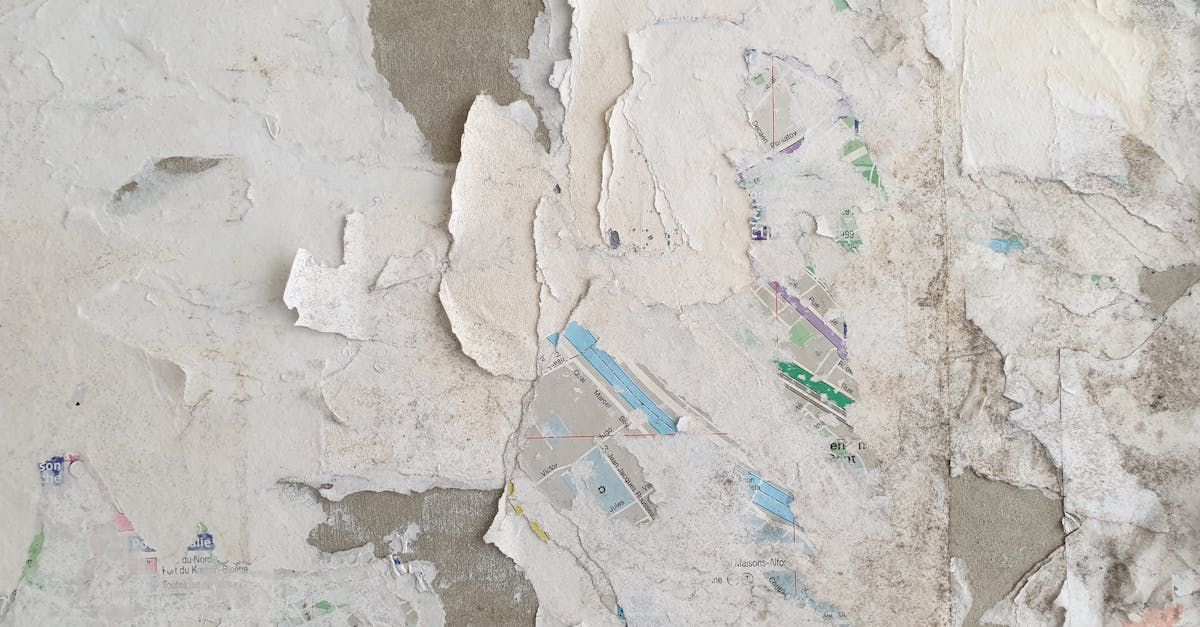

Skim coating is a crucial technique in interior

home renovations, especially for those aiming to achieve perfectly smooth walls. This plastering method not only prepares walls for painting but also plays a significant role in the overall aesthetics and longevity of your wall treatments. Below, we dive into the different types of skim coatings, explore the importance of quality, and offer tips for both DIY enthusiasts and those considering

professional services.

Types of Skim Coatings

Skim coating can be done using different types of joint compounds, each suited to specific needs and scenarios. Understanding the types can help you choose the best option for your project:

All-Purpose Joint Compound

Ideal for both taping and top coating, all-purpose compounds are versatile and widely used for skim coating. They are easy to sand and generally have good adhesion properties.

Topping Compound

Lighter and easier to spread, topping compounds are excellent for the final layers of a skim coat. They provide a smooth finish and are easier to sand than all-purpose compounds.

Setting-Type Joint Compound

Known for its quick setting times, this compound is perfect for projects that require a faster turnaround. It is harder when set, making it durable but more difficult to sand than other types.

The Skim Coating Process: A Step-by-Step Overview

Preparation

Proper preparation is key to successful skim coating. This involves cleaning the walls, repairing any significant damage, and applying a primer if necessary to ensure the compound adheres properly.

Application

Using the right tools, such as a wide drywall knife or trowel, apply the joint compound in thin layers. It's crucial to work in sections and use smooth, consistent strokes to achieve an even coat.

Sanding and Priming

Once the skim coat is dry, sand the surface to a fine finish, being careful not to gouge the newly smoothed wall. Apply a primer to create an optimal surface for painting, ensuring longevity and quality appearance.

Quality and Its Importance in Skim Coating

The quality of materials and application in skim coating directly affects the end result. High-quality joint compounds ensure better adhesion, a smoother finish, and reduced likelihood of future issues such as cracking or peeling. Furthermore, skilled application ensures that the skim coat is free from tool marks and imperfections, which are crucial for aesthetic reasons and the structural integrity of the wall.

Why Quality Matters:

Durability: High-quality skim coating resists wear and tear over time, maintaining its appearance and integrity.

Aesthetics: A smooth, flawlessly applied skim coat provides an ideal canvas for paint or other finishes, enhancing the room's appearance.

Value: Investing in quality skim coating can increase the value of your home by improving the overall finish and appeal of your interiors.

Cost Considerations in Skim Coating

The cost of skim coating walls varies based on the area's size, the condition of the walls, and whether you choose to DIY or hire a professional. As mentioned earlier, typical costs range from $1.00 to $1.50 per square foot, but can increase if the walls require extensive prep work or if high-end materials are used.

DIY vs. Hiring Professionals:

While DIY can be cost-effective, the benefits of professional application often outweigh the initial savings. Professionals ensure a uniform, high-quality finish, and their experience can prevent costly mistakes that might arise from inexperience.

Conclusion

Understanding the different types of skim coatings and the importance of quality is essential for anyone looking to enhance their home's interior walls. Whether you're preparing to paint or just looking to improve your home's aesthetic, skim coating is a valuable skill that can significantly impact the outcome of your renovation projects. Always consider the balance between cost and quality to ensure that your investment in skim coating yields beautiful, long-lasting results.

Ready to work with Dallas Drywall Contractor Pros?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 469-908-1924